We specialize in recycling materials which contain precious metals.

REDISCOVERING VALUE

WHAT DO WE BUY

Ceramic catalysts

The majority of vehicle catalysts currently in use are based on a ceramic core, which’s honeycomb structure holds a catalytically active precious metal coating of platinum, rhodium and palladium.Metal catalysts

Metal catalysts end up in the recycling process in ever increasing numbers. They offer an alternative to ceramic catalysts not only in vehicles but in numerous other fields of application as well.Industrial Catalysts

Catalysts have numerous industrial applications in both emission purification and production. They are as essential in the realm of Bio-fuel production and environmental technology as in Oil refinement and the chemical industry.Diesel particulate filters

Particulate filters reduce the amount particles in the emission of Diesel engines. They are based on a ceramic honeycomb structure, most often coated with an amalgamation of precious metals.Lambda probes

They are merely a few centimeters in size, but fulfill an essential task. They are sensors that measure the ratio of fuel and oxygen in the emissions of a combustion process.Miscellaneous precious metal materials

Precious metals cannot only be found in catalysts, but in numerous industrial products, production residue and other materials as well.RECYCLING PROCESS

If you are looking for an honest and fair recycling partner for your old catalytic converters or other materials containing precious metals, you have come to the right place. We offer transparent procedures and reliable processing, from advice and purchase to billing and recovery. Qualified, experienced specialists and high-performance technology are available for this.

Value assessment

The precious metal content of the more than 10,000 types of catalyst available varies greatly. The valuation is carried out either with the help of our extensive database or through a laboratory analysis.Purchase

We buy metal and ceramic catalytic converters from vehicles, industrial catalytic converters and diesel particulate filters, as well as lambda sensors and other materials containing precious metals - and at fair prices.Consulting

We understand our business, we know the market and the wishes and questions of our customers. We are happy to share our know-how with you and advise you on all issues relating to precious metal recycling and valuation.Processing

In addition to complete processing, we offer you various reworking solutions for your material, be it monoliths, broken monoliths or metal catalysts.RECYCLING PROCESS

If you are looking for an honest and fair recycling partner for your old catalytic converters or other materials containing precious metals, you have come to the right place. We offer transparent procedures and reliable processing, from advice and purchase to billing and recovery. Qualified, experienced specialists and high-performance technology are available for this.

Value assessment

The precious metal content of the more than 10,000 types of catalyst available varies greatly. The valuation is carried out either with the help of our extensive database or through a laboratory analysis.Purchase

We buy metal and ceramic catalytic converters from vehicles, industrial catalytic converters and diesel particulate filters, as well as lambda sensors and other materials containing precious metals - and at fair prices.Processing

In addition to complete processing, we offer you various reworking solutions for your material, be it monoliths, broken monoliths or metal catalysts.Consulting

We understand our business, we know the market and the wishes and questions of our customers. We are happy to share our know-how with you and advise you on all issues relating to precious metal recycling and valuation.NEWS

We are pleased to present you the latest news from ReMetall.

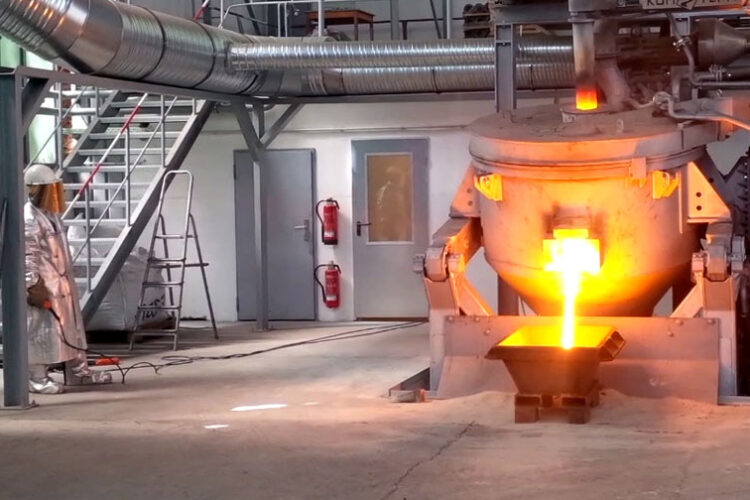

Smelting plant

Equipped with an electric arc furnace, enabling us to smelt precious metal monoliths at 1500 degrees Celsius......

Coronavirus safety regulations

We take the health of our colleagues and customers very seriously. Our new pandemic agenda includes…

New lab equipment

Our laboratory recently acquired a LECO TGA801. The device is capable of obtaining high-resolution mass spectral data from even the most complex samples.

OUR SERVICES

Our team of experts consists of professionals who have worked in the recycling industry for a long time.

We offer you consulting services, recycling solutions for precious metals as well as a comprehensive approach to any challenge and extensive assistance for our customers.

CONSULTING

VALUE ASSESSMENT

PROCESSING

REMETALL Deutschland AG

Find out more about our company and our services.

Contact Us

Still any questions? Contact us with your request. We are happy to use our expertise to advise you comprehensively.

ReMetall Deutschland AG